Who is Impacted?

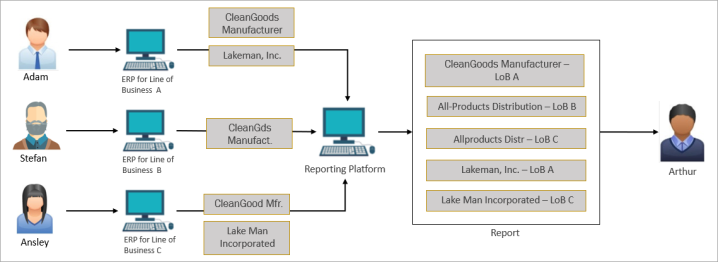

Adam, Stefan, and Ansley are representatives on the procurement team. They are each responsible for managing ACME supplier data within the ERP applications that support each line of business.

Arthur, a specialist on the procurement team, is responsible for compiling / analyzing reports and performance KPIs for suppliers from whom ACME purchases raw materials, finished goods and services.

What is the Business Problem?

ACME’s supplier data is currently managed across multiple different ERP source systems due to differences in territories and lines of business. Since suppliers may conduct transactions across multiple territories, managing the same suppliers across multiple source systems is a challenge as the source systems lack the capability to synchronize with each other.

Due to this siloed landscape, the lack of synchronization between the various ERP presents operational challenges. This introduces discrepancy in the customer data which currently cannot be managed or mitigated. For example, Adam may update an address or other contact information for a particular supplier that is also managed by Ansley within a different ERP.

Current Process

With multiple points of data entry in this process, supplier data is prone to duplicates across ERPs as well as incomplete and conflicting information being introduced. Furthermore, although data is synchronized from each ERP application to ACME’s reporting platform, there is no reliable process for aggregating customer data. Arthur cannot conduct validity checks and other governance measures required by the business; therefore, the reports that they compile and provide for downstream business operations are prone to inaccuracies.

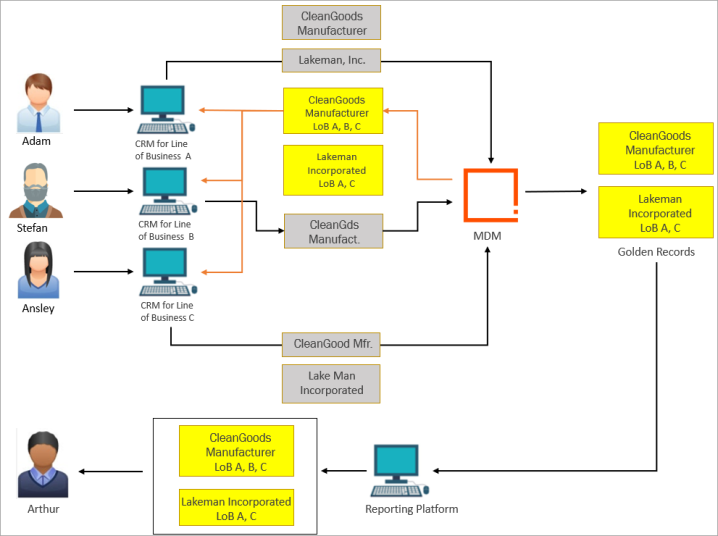

Future Process

An MDM solution will provide the ERP applications the means to preemptively search within MDM for supplier records before new records are created in CRM. If the supplier already exists based on minimal search parameters, MDM will provide the identifier of the record. If the supplier does not exist in MDM, then Adam, Stefan, and Ansley may proceed with creating the new record in ERP.

MDM will then aggregate supplier data from the ERP source systems for all lines of business and automates business validations to ensure completeness and accuracy. The resulting golden supplier record(s) are sent to downstream systems to facilitate other business operations. MDM will also synchronize the mastered supplier data back with upstream ERP source systems.

This process ensures the synchronization of mastered supplier data across all ERP applications which provides Adam, Stefan, and Ansley with accurate and up-to-date customer data. As a result, all ERP source systems now have the same, up to date address information available.